11 Apr 2025

Most small molecule drugs are formulated as oral solid dosage (OSD) forms, such as tablets or capsules. OSD has been an important part of the global pharmaceutical market.

The formulation team of Crystal Pharmatech is formed by technical experts with considerable experience in formulation development and dosage form optimization. We design and develop the solid dosage form and process tailor-made for your molecule based on a deep understanding of the material properties of API and to meet its intended clinical needs.

Examples of dosage forms we can develop include:

Tablet: Immediate Release (IR), Controlled Release (CR), Bilayer, Mini-tablet

Capsule: Powder, Granules, Multi-particulates, Mini-tablet in capsule

Multi-particulates

Equipped with the top-of-the-line equipment and notch instruments, our formulation team will collaborate with for to deliver formulation and process:

Formulation Process:

Wet Granulation

Dry Granulation

Blending

Milling

Compression

Encapsulation

Pan Coating

Fluid Bed Coating

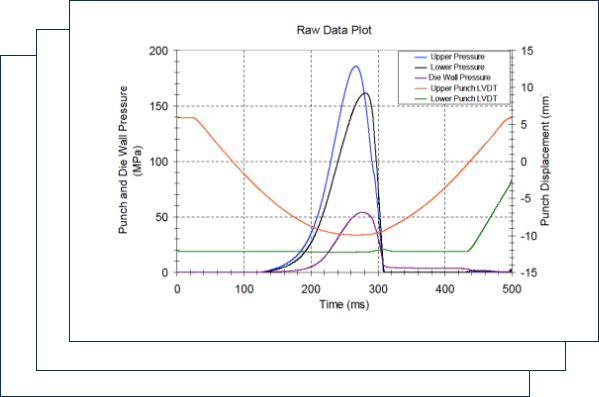

Compaction simulation is one of the core technologies at Crystal Pharmatech. It can be used to characterize compaction properties of neat API, excipients, and blends, which will guide formulation development strategy. Specifically, it can simulate the compression process parameters, such as main compression force, precompression force, dwell time, etc., from lab, pilot to commercial scale tableting machines. In addition, it can simulate the roller compaction process, e.g. predict the roll pressure for all kinds of dry granulators. With only a few grams of material, the compaction simulator can predict compression parameters for commercial machines with hundreds of kgs scale. It becomes one of the most efficient and reliable tool for the design and scale-up of the dry granulation and tableting process.