01 Feb 2023

/ Formulation Right

/ Formulation Right

the First Time /

In recent years, amorphous solid dispersions (ASD) have attracted attention due to their ability to significantly improve the solubility of poorly soluble drugs. Since the drug molecules in ASD are in a high-energy state, there is a tendency for spontaneous transformation into a low-energy crystal form, resulting in physical stability issues such as phase separation and crystallization during storage, which in turn affects the stability and bioavailability of the formulation. Therefore, maintaining the stability of ASD during the product's shelf life is the primary requirement for its development. This article aims to briefly introduce several key factors affecting the physical stability of ASD.

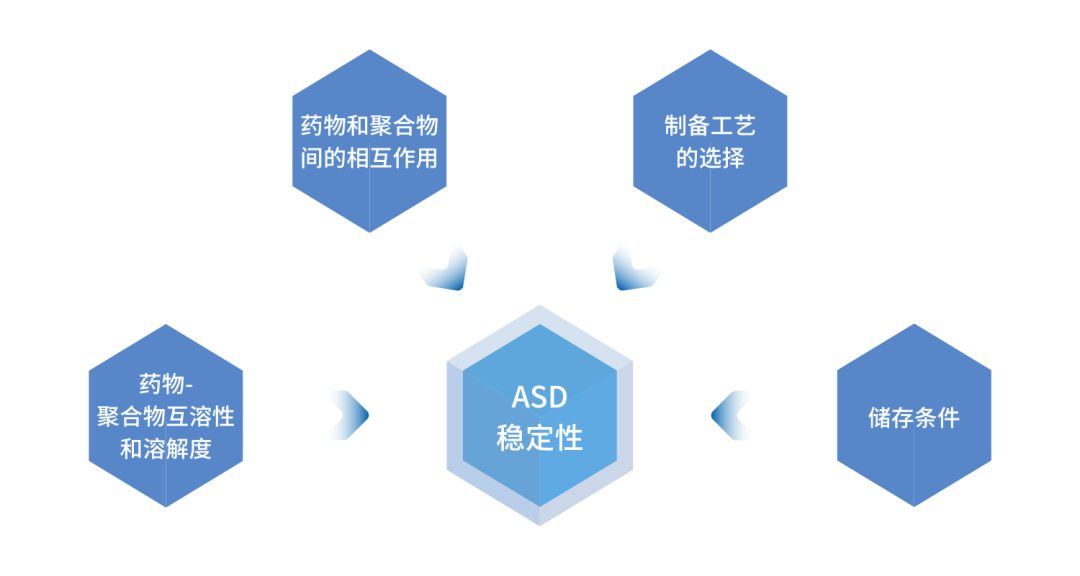

In order to develop stable and reliable ASD formulations, the following factors need to be carefully considered in the process of selecting polymers, choosing preparation processes, and storage conditions: drug-polymer miscibility, drug solubility in the polymer, drug-polymer interactions, production processes, and storage conditions.

Various factors affecting the stability of ASD are shown in Figure 1.

Figure 1 provides an overview of the key factors influencing the stability of amorphous solid dispersions (ASD).

Figure 1 provides an overview of the key factors influencing the stability of amorphous solid dispersions (ASD).

Drug-

Polymer Miscibility and Solubility

The miscibility of drugs and polymers and the solubility of drugs in the polymers are the main prerequisites for the development of ASD. ASD is a homogeneous system that requires the drug and polymer to be miscible. The higher the miscibility between the drug and polymer, and the higher the solubility of the drug in the polymer, the higher the drug loading capacity of the ASD. If the concentration of the drug in the carrier is lower than its solubility in the carrier at the storage temperature, then the ASD is stable; otherwise, if the drug is in a supersaturated state in the carrier, the ASD has a higher chemical potential energy, and the drug molecules are prone to crystallization, thus affecting the product quality. Therefore, it is crucial to select miscible polymers for the development of stable formulations with high drug loading capacity.

Drug-Polymer Interactions

Drug-polymer interactions play an important role in the physical stability of ASD. The enhancement of stability through drug-polymer interactions mainly has two aspects. Firstly, drug-polymer interactions, such as hydrogen bonding and ion-dipole interactions, can reduce the molecular mobility of the drug in the ASD, thereby enhancing the physical stability of the ASD. Generally, the stronger the drug-polymer interactions, the higher the stability of the ASD. Secondly, drug-polymer interactions can affect the miscibility of the drug and polymer as well as the solubility of the drug in the polymer, thereby affecting the stability of the ASD.

Selection of Preparation Process

The preparation method and process have a significant impact on the stability of amorphous solids. Different preparation processes result in significant differences in physical stability of solid dispersions, as molecular interactions and physicochemical properties induced by different solid dispersion preparation processes vary, leading to different key factors affecting physical stability, such as drug dispersion, microstructure, and disruption of drug lattice. Hot melt extrusion and spray drying are currently the most commonly used ASD preparation methods. From a crystallization perspective, products prepared by hot melt extrusion have low specific surface area and high bulk density, while products prepared by spray drying have low bulk density and high specific surface area, which may make them more susceptible to moisture absorption. More moisture absorption may lower the glass transition temperature of the ASD, thereby increasing the risk of re-crystallization. Therefore, storage conditions, particularly for spray-dried ASD, need to be carefully controlled to mitigate the risk of re-crystallization caused by moisture absorption.

Storage Conditions

One important factor affecting the stability of ASD is the glass transition temperature (Tg). Since ASD is a single-phase system, it has a single Tg. When the storage environment temperature is higher than Tg, molecular mobility increases, and the tendency for crystallization increases. Therefore, ASD needs to be stored at temperatures much lower than Tg. Since most ASD carriers are hydrophilic materials and have strong hygroscopicity, absorbed moisture acts as a plasticizer and lowers the Tg of the system. Therefore, ASD needs to avoid the influence of environmental moisture. Choosing packaging materials with good moisture barrier properties, sealing, and low-temperature storage are effective measures to maintain the physical stability of solid dispersions.

Over the past two decades, ASD methods have received considerable attention compared to other methods for improving the solubility and bioavailability of poorly soluble drugs, and the stability of ASD has become an important issue to be addressed in the drug development process. Numerous studies and successful cases have shown that by selecting suitable polymers, designing rational formulations, choosing appropriate preparation processes, and strictly controlling storage conditions, the quality and stability of ASD formulations can be maintained, making ASD an increasingly preferred formulation approach for the development of poorly soluble drugs.